Home » About Us

The foundations for the Australis Group were laid in August 1983 when Phillip and Stephanie Gustafson founded Ribuli Pty Ltd, a small mechanical engineering job shop that specialised in metal fabrication and maintenance of machinery used in manufacturing environments. This family owned and operated business grew quickly and moved to premises at Padstow where it was renamed Australis Engineering and quickly developed a reputation for high quality, and efficiently designed machinery for the food, beverage and pharmaceutical industries.

During the late 1980’s and into the 1990’s, Australis refined and developed its range of Air Flow Conveyors for PET bottles, winning large projects at major beverage manufacturers including Coca-Cola, Pepsi/ Schweppes, Orchy, Dairy Farmers and P&N Beverages. This success saw the company export a large number of air flow conveyors within the region, including Vietnam, New Zealand and Fiji. Many new clients came on board, especially in the pharmaceuticals sector where local manufacturing was still common.

With success came risk however as Australis was exposed to technology changes which would eventually see air flow conveyors become much less prominent in the handling of PET bottles. This necessitated the pivot towards automation in the late 1990’s and early 2000’s. While we had always implemented basic automation and line control, the business knew it needed to embrace these rapidly emerging technologies, with then undergraduate Mechatronics Engineer, Anthony Gustafson joining the business.

This lead briefly to the birth of our second company, Australis Automation. Australis Automation began in 2005 with the aim of providing industrial automation services to clients. It quickly became evident that running the two businesses side by side was inefficient and the automation functions were rolled into Australis Engineering in early 2007. By this stage Anthony was a fully qualified Mechatronics Engineer and was being groomed to take-over the engineering functions of the business and with it was bringing further ideas regarding the future evolution of the business including with a stronger focus on robotics.

In late 2007, Australis achieved two significant milestones. It successfully won the multi-million dollar tender to provide the new circulating coin, Materials Handling and Warehousing System at the Royal Australian Mint in Canberra. The RA Mint project was a watershed for the business, incorporating multiple robots, multiple AGV’s and a full factory automation system which enables the production of over 15 million coins per week and including some innovative, world-first solutions including a safe, integrated passenger/ goods lift AGV movements and a revolutionary vision counting system capable of counting up to 22,000 coin blanks per minute at 99.99% accuracy. It also marks the year that Australis first achieved its ISO9001 Quality Management certification, which it still maintains today and which is a cornerstone of our operations.

In 2009, as Phillip and Stephanie rapidly moved towards retirement, eldest son Peter Gustafson joined the business full-time to take on the MD role. Together Peter and Anthony quickly relocated the business from it long-term rented location at Padstow, to a new factory purchased at 25 Harley Crescent, Condell Park. This change permitted the rapid growth of its sales and engineering teams and with it, the ability to service larger and more complex projects and to further add new products and capabilities to our portfolio.

In 2010, this resulted in the addition of the PROFILIUM business to the Group. Profilium is focused on importing, selling and utilising t-slot aluminium profiles into the Australian market. With a strong partnership forged with Italian manufacturer, Alusic SRL, Profilium began selling t-slot profiles B2B and B2C across Australia using its dedicated website. Distribution arrangements were quickly established in Melbourne and Brisbane and today Profilium is one of the primary suppliers of t-slot aluminium profile into the Australian market. It has worked closely with Alusic to introduce new products, including a black anodized t-slot profile which is an Australian exclusive for Alusic.

During the mid-2000’s the Australian manufacturing landscape continued to change, with many more businesses deciding to off-shore their manufacturing and to focus on local warehousing and distribution. Australis responded by quickly developing a stronger range of pallet conveyors and other pallet handling equipment and in particular began to develop its own robotic palletising software system.

With a greater diversity of products, Australis have been able to broaden its client mix, and while food, beverage and pharmaceuticals are still important, we also have many clients in the health, medtech, industrial, packaging, warehousing, building & construction and hazardous substance sectors. We even dabble in the aerospace, rail, mining and automotive sectors, especially via Profilium’s offering of t-slot aluminium profiles.

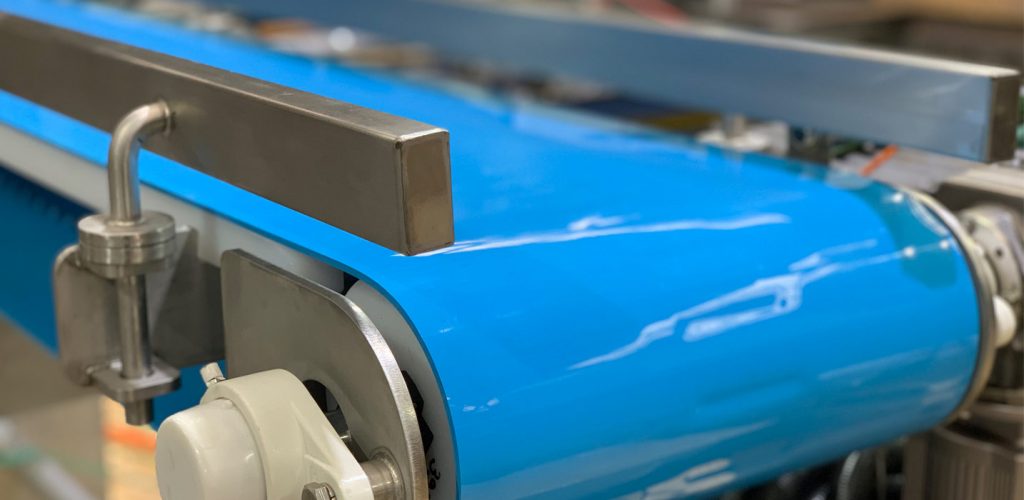

In 2018, Australis made the decision to focus on R&D of some new products, resulting in the launch of our proprietary simPAL® Robotic Palletising system and our Hygenius™ Ultra-Clean Conveyor system. simPAL also represents the first time we have achieved a Registered Trademark for one of our solutions.

2018 was also momentous for another reason, as we shifted away from our long-time “Kangaroo Logo” and our red, white and blue colour scheme to our current Black and Gold scheme with the AE “brain” logo and our tagline of Smart Thinking in Motion.

Late 2018 into 2019 also saw the expansion of our robotics offerings, with Australis being appointed one of two Australian distributor’s for Techman Robot collaborative robots and for a range of small automated robots and AGV’s by Passion Mobility and the MAX Cleaning Robot by UniRing. By 2022, Australis Engineering had even graduated to being the primary Australian Distributor of Techman Robots.

The inclusion of cobots, mobile robots and AGV’s into our standard materials handling product mix has resulted in new opportunities with existing clients and the expansion into new markets including the retail food and beverage services space, where both cobots and AGV’s continue to show huge potential.

The Advance Conveyors business joined the group in early 2020 and brings a strong history and reputation of conveyor manufacturing. Advance Conveyors was founded in 1995 and had developed into a highly regarded provider of conveyors and conveyor components and spares, with an especially strong reputation for gravity and powered roller conveyors. While conveyors remain core business for Australis, we had moved away from fabricating roller conveyors due to our cost structures making it unviable. The inclusion of Advance Conveyors into the group alters this and allows Australis and Advance to work together to provide timely and highly cost effective, locally manufactured conveyor solutions – something that’s become even more critical in the Australian market in the COVID disrupted world. Since joining the Group, Advance have gone from strength to strength, winning new business across Australia and continuing to be one of the primary suppliers of roller conveyors and roller conveyor components to the OEM and reseller market.

With Australis Engineering, Profilium and Advance Conveyors all occupying the same space at 25 Harley Crescent, things were getting tight! We needed more space as all of the businesses saw rapidly increasing demand off the back of the COVID pandemic and disruption to global supply chains which was forcing local business to revisit their supply chain decisions. With space at an absolute premium (manufacturing in your carpark is not ideal!), the Group purchased the property directly behind 25 Harley in early 2021.

The addition of 3 Harley Crescent more than doubles the fabrication and warehouse size for Australis, Profilium and Advance, providing over 2,300 square metres of fabrication space and makes our operations more efficient, while more easily permitting projects of larger scale to be fabricated and tested prior to install and commissioning.

However, the most significant addition to the Group is the acquisition of the Precision Stainless System business, based in Darra (Brisbane) Queensland. Precision joined the group in April 2021 and provides multiple benefits to the Group. Most importantly they have built one of the most outstanding industry reputations for high quality and on-time delivery of stainless-steel machinery and structures. With very strong conveyor capabilities, they fit neatly into the capabilities within the Group, but also bring an established entry-point into the raw food sector and in particular the meat and abattoir sector. This will allow the further sale of Hygenius™ Conveyors and the expansion of the market for Advance roller conveyors and Australis’ automation and robotics capabilities. It also plugs a gap for Profilium, but providing a new outlet for Queensland based sales of t-slot aluminium profile. With huge growth happening at Precision, they were relocated to larger, more modern facilities at Richlands, QLD.

Importantly, PSS brings its significant manufacturing expertise to the Group, further enhancing our ability to offer large scale conveyor systems and bringing the Group’s total manufacturing space to over 5,000 square metres.

The combination of Australis Engineering, Precision Stainless Systems, Advance Conveyors and Profilium brings scale and efficiency to our Australian manufacturing capabilities. While across the group we all offer outstanding conveyor expertise, each business also brings its own competitive advantage, whether it’s robotics and automation, low-cost and timely conveyor systems, versatility of t-slot profile or the high-quality, stainless solutions with access to the meat and raw foods markets, the Australis Group now offers a smart, automated solution for customers, regardless of the scale or location of your project.